5 Best Electrical Tape for Wiring Harness (2025 Guide)

Wiring harness projects demand more than just any roll of tape they require electrical tape that can handle heat, tension, and long-term durability.

Using the wrong tape could lead to loose connections, early wear, or even safety hazards. That’s why professionals and DIYers alike turn to trusted electrical tapes designed specifically for wiring harness applications.

In this guide, we’ll break down the 5 best electrical tapes for 2025, comparing their strength, flexibility, heat resistance, and overall value, so you can choose the right option to keep your wiring secure and reliable.

Electrical tape is an unsung hero in any toolbox, but when it comes to a task as critical as building or repairing a wiring harness, not all tapes are created equal. A wiring harness is more than just a bundle of wires; it’s the central nervous system of a vehicle, machine, or electronic device. It organizes, protects, and connects dozens of individual wires, ensuring they are shielded from heat, abrasion, moisture, and vibration.

Choosing the right tape for this job isn’t about finding the cheapest option; it’s about investing in safety, reliability, and long-term performance. The right tape will conform to complex shapes, withstand extreme conditions, and provide a secure, lasting bond without becoming brittle or gooey. It acts as the final line of defense against electrical shorts and system failures.

In this comprehensive guide, we’ll explore what makes a great electrical tape specifically for wiring harnesses. We’ll dive into the top five market leaders, providing a detailed breakdown of their features, pros, and cons to help you make the best choice for your project, whether you’re a professional electrician or a dedicated DIY enthusiast.

Best Electrical Tape for Wiring Harness – Top 5 Picks

1. 3M Scotch Super 33+ Electrical Tape (Best Overall)

If there is one name that dominates the electrical tape industry, it’s 3M. Their Scotch Super 33+ is widely regarded as the gold standard for professionals and for good reason. It’s a premium-grade, all-weather vinyl tape that excels in virtually every performance category, making it our top pick for any serious wiring harness project.

- Features & Specs: The Super 33+ is a 7-mil (0.178 mm) thick polyvinyl chloride (PVC) tape with a pressure-sensitive, rubber-based adhesive. It is UL Listed and CSA Certified, ensuring it meets strict safety standards. This tape is rated for continuous use in temperatures from 0°F to 220°F (-18°C to 105°C) and can handle up to 600 volts. Its key selling point is its incredible conformability and elasticity, allowing it to stretch significantly without breaking. It is also highly resistant to abrasion, moisture, alkalis, acids, and UV rays.

- Pros:

- Unmatched Performance: The combination of an aggressive adhesive and a flexible backing provides a moisture-tight, mechanically sound seal with minimal bulk. It hugs wires perfectly, even in complex bends and splices.

- All-Weather Resilience: It is designed to perform flawlessly in a wide range of temperatures, from freezing cold to scorching hot, making it perfect for engine bays and outdoor applications.

- Professional Trust: As the go-to tape for electricians and technicians, its reputation for reliability and longevity is second to none. It won’t flag (peel up) or become sticky and messy over time.

- Cons:

- Price Point: The main drawback is its cost. It is significantly more expensive than most general-purpose electrical tapes, but for a critical application like a wiring harness, the investment in quality is well worth it.

- Slight Residue: In rare cases, if left on a surface for an extremely long time in a high-heat environment, it may leave a very slight adhesive residue upon removal.

2. Duck Professional Electrical Tape (Best for Durability)

Duck Brand has a long history of producing high-quality tapes, and their Professional Electrical Tape is a strong contender, particularly when durability is the top priority. This tape is built to be rugged and tough, standing up to demanding conditions where other tapes might fail.

- Features & Specs: This is a heavy-duty vinyl electrical tape, often with a 7-mil thickness, designed for professional use. It is UL Listed and CSA Certified, rated for up to 600 volts and a temperature range of 14°F to 176°F (-10°C to 80°C). Its durable vinyl backing is resistant to abrasion, moisture, and solvents, and it has a robust adhesive that provides a strong, lasting bond.

- Pros:

- Rugged Construction: The Duck Professional tape is known for its tough, abrasion-resistant backing. It’s an excellent choice for a wiring harness that will be exposed to frequent friction or rough surfaces.

- Strong Adhesion: Users consistently praise its strong adhesive, which provides a secure and reliable hold that resists peeling.

- Reliable Performance: This tape delivers a dependable performance that can withstand the rigors of an engine bay, including exposure to water and flame.

- Cons:

- Less Flexible: Due to its heavy-duty construction, this tape is not as stretchy or conformable as the 3M Super 33+. It may be more difficult to apply smoothly around extremely tight bends or irregular shapes without some wrinkling.

- Limited Temperature Range: While its temperature range is respectable, it is not as wide as that of the 3M Super 33+, making it slightly less suitable for the most extreme cold-weather applications.

3. Amazon Commercial Electrical Tape (Best Value Pack)

For a large-scale project where you need a substantial amount of tape without a premium price tag, the AmazonCommercial Electrical Tape is an excellent choice. It’s a versatile and cost-effective solution that provides a surprising level of quality for the price, making it ideal for bulk jobs or for those on a tight budget.

- Features & Specs: Typically sold in multi-roll value packs, this tape is a flexible vinyl option. It is flame-resistant and water-resistant, with a thickness and voltage rating comparable to many standard commercial tapes. It comes in a variety of colors, which is a major benefit for color-coding different sections of a complex wiring harness.

- Pros:

- Unbeatable Value: The most obvious advantage is the price. For the cost of a single roll of a premium brand, you can get a multi-pack of AmazonCommercial tape, which is perfect for hobbyists or DIYers who need to tape a lot of wires.

- Versatile: The availability of multiple colors makes this tape incredibly versatile for professional-looking, color-coded harnesses. You can easily tear pieces by hand for quick applications.

- Solid Performance: Despite the low cost, it offers reliable performance. It’s flame-resistant and water-resistant, providing adequate protection for general-purpose wiring harnesses that are not exposed to the most extreme conditions.

- Cons:

- Lower Temperature Adhesion: Some users have reported that the adhesive may not perform as well in lower temperatures, which could be a concern for cold-weather applications.

- Not as Rugged: This tape is not as durable or abrasion-resistant as higher-grade professional options like the Duck or 3M tape. For harnesses that face frequent friction, you might need to apply multiple layers.

4. Lichamp Black Electrical Tape (Best for Professionals)

Lichamp Black Electrical Tape is a strong, industrial-grade option that has built a solid reputation among professionals for its consistent performance and value. Often sold in multi-packs, it offers the durability and safety features that experts demand, making it a reliable tool for high-stakes projects.

- Features & Specs: This tape is a 7-mil thick, industrial-grade vinyl tape. It is UL and CSA listed, which provides peace of mind regarding its safety and compliance. It is rated for up to 600 volts and a temperature range of 0°F to 176°F (-18°C to 80°C). The tape is lead-free, flame-retardant, and resistant to sun, water, oil, and chemicals.

- Pros:

- Professional-Grade Quality: This tape delivers on its promise of professional quality. Its robust adhesive and tough backing ensure a secure, long-lasting bond that won’t degrade easily.

- Excellent Resistance: Its resistance to a wide range of elements, including oil, acids, and alkalis, makes it an ideal choice for wiring harnesses in automotive or industrial environments where fluids and chemicals are present.

- Trusted Certifications: The UL and CSA listings confirm that this tape has been tested to meet stringent safety and performance standards.

- Cons:

- Slight Chemical Odor: A few consumers have noted a slight chemical smell upon unrolling the tape, though this is a minor issue that dissipates quickly.

- Less Elastic: While strong, it can be slightly less stretchy and conformable compared to premium tapes like the 3M Super 33+, which may require more care during application to achieve a smooth finish.

5. Cambridge Vinyl Electrical Tape (Best for DIY Projects)

The Cambridge Vinyl Electrical Tape is a great choice for homeowners and DIYers who need a reliable, high-quality tape for a variety of projects. It is widely available, often sold in convenient multi-color packs, and offers a balanced combination of features that make it a dependable tool for everyday wiring tasks, including small-scale wiring harness projects.

- Features & Specs: This tape is a professional-grade, 7-mil thick vinyl tape. It is UL Listed and lead-free, ensuring safety for home use. It is flame-resistant and offers good resistance to UV, water, and oil. The tape is rated for a temperature range of 14°F to 176°F (-10°C to 80°C) and a voltage of up to 600V.

- Pros:

- Good All-Rounder: The Cambridge tape is a solid performer across the board. It is flame-resistant, UV-resistant, and water-resistant, making it a versatile choice for a range of wiring projects.

- Value and Convenience: Available in multi-packs and various colors, it provides excellent value and makes color-coding simple and efficient.

- Easy to Use: This tape is flexible enough for easy application and provides a strong, reliable bond for most DIY wiring projects.

- Cons:

- Adhesion Not as Strong: Compared to the top professional brands, the adhesive on the Cambridge tape is not as aggressive. While it is more than sufficient for general use, it may not hold as well in extremely high-stress or high-vibration applications.

- Not for Extreme Conditions: Its performance may be limited in the most extreme conditions where a more rugged, industrial-grade tape would be required.

When embarking on any electrical project, the tools you choose are just as important as the skills you possess. This is especially true when creating or repairing a wiring harness. A wiring harness is far more than a simple bundle of wires; it is the organizational core of an electrical system, protecting cables from the harsh realities of their environment. Whether a wiring harness is found in an automobile’s engine bay, a piece of industrial machinery, or a home appliance, it must be resilient. It needs to withstand constant vibration, extreme temperatures, and exposure to moisture and chemicals.

The quality of the electrical tape used on a wiring harness directly impacts its safety and longevity. A cheap, general-purpose tape can become brittle, lose its adhesion, or degrade into a sticky mess, leaving wires exposed and vulnerable to shorts and failures. A premium, purpose-built tape, however, will provide a durable, long-lasting protective jacket. This guide is designed to help you navigate the essential features of electrical tape, ensuring you select the perfect one for your wiring harness project.

Buying Guide – What to Look for in Electrical Tape for Wiring Harness

Material Quality (Vinyl vs. Rubber)

The foundational choice you’ll make when selecting an electrical tape is its material. The vast majority of electrical tapes are made from either vinyl or rubber, each with unique properties that make them suitable for different applications. Understanding the differences is the first step toward making an informed decision.

- Vinyl (PVC) Electrical Tape: Vinyl is the most common and versatile material for electrical tape. Its popularity comes from its excellent combination of properties: it is highly flexible, stretchable, and conformable. This makes it ideal for wrapping around complex shapes and tight bends within a wiring harness. High-quality vinyl tape is also resistant to moisture, UV rays, acids, alkalis, and abrasion. Most general-purpose and professional-grade electrical tapes are vinyl-based. They have a strong, pressure-sensitive adhesive on one side that bonds securely to itself and to the wires, creating a smooth, protective outer jacket. For most low-voltage wiring harnesses in consumer electronics or automotive engine bays, a premium vinyl tape is the perfect choice due to its durability and ease of application.

- Rubber Electrical Tape: Rubber tape, often made from self-fusing ethylene propylene rubber (EPR), operates on a different principle. It typically has no adhesive. Instead, when you stretch and wrap it, the layers of tape fuse together to form a solid, moisture-tight, and highly insulating barrier. Rubber tapes are known for their exceptional thermal and electrical properties. They have a high dielectric strength and are often used for high-voltage applications or for sealing connections to prevent moisture ingress. While rubber tape is less common as a primary harness wrapping material, it is an invaluable tool for certain applications. For example, it is used to seal a wire splice within a harness, providing a waterproof barrier, and is then often over-wrapped with a layer of vinyl tape for mechanical protection and abrasion resistance.

- Other Materials and Alternatives:

- Cloth/Fleece Tape: Widely used in automotive manufacturing, this tape is made of woven fabric. It is known for its incredible abrasion resistance and its ability to reduce rattling noises in a vehicle. It is often preferred for harnesses that are routed through the cabin or areas with significant vibration.

- Liquid Electrical Tape: This product is a brush-on, rubber-based coating that air-dries into a durable, flexible, and waterproof insulation. It’s an excellent option for sealing connections in hard-to-reach areas or for providing a seamless, custom-fit protective layer that traditional tape cannot achieve.

In summary, for general-purpose wiring harnesses, a high-quality vinyl tape offers the best balance of flexibility, durability, and cost. For specific needs, like waterproofing a splice or adding a layer of vibration dampening, rubber or cloth tapes may be a more specialized solution.

Adhesion Strength & Flexibility

A tape’s ability to stick and conform is arguably its most critical feature for a wiring harness. A tape that doesn’t adhere well will “flag,” meaning its ends will peel up, leaving the wires exposed and the harness looking unprofessional. A tape that lacks flexibility will wrinkle and leave gaps during application, compromising its protective barrier.

- Adhesion Strength: High-quality tapes are formulated with a strong, long-lasting adhesive that maintains its bond over time and across a wide range of conditions. For a wiring harness, where wires are often subject to vibration and minor movement, the adhesive must be robust enough to prevent slippage and unraveling. A tape with a weak adhesive will ultimately fail, allowing the wires to shift and potentially chafe against each other. When evaluating a tape, check its adhesion rating, often measured in ounces per inch. A higher number indicates a stronger bond.

- Flexibility and Elasticity: A wiring harness is rarely a straight line. It has multiple wires, branches, and bends. A highly flexible and elastic tape is essential for a professional finish. It allows you to apply a smooth, wrinkle-free wrap that tightly hugs the contours of the wires. High elasticity means the tape can stretch to more than twice its original length without breaking, which is perfect for creating a tight, sealed jacket. This “memory” or “recovery” also allows the tape to continue to contract slightly after application, further compressing the harness and creating a tighter, more protective wrap.

A balance of strong adhesion and high flexibility is key. Some tapes prioritize rigidity for superior abrasion resistance, while others focus on conformability. Your choice should reflect the specific needs of your project.

Heat & Cold Resistance

A wiring harness, especially one in an automotive engine bay, is exposed to a dramatic range of temperatures. A tape that performs well in a climate-controlled workshop may become brittle and crack in freezing weather or melt and turn to goo under the heat of a running engine.

- Heat Resistance: The temperature rating of electrical tape is crucial. It indicates the maximum temperature at which the tape can maintain its properties without degrading. For engine bay applications, look for a tape with a high-temperature rating, typically above 176°F (80°C). Premium, professional-grade tapes are often rated for up to 220°F (105°C), ensuring they will not lose their adhesion or become a sticky mess even in hot environments. A tape that breaks down under heat can expose wires, leading to a dangerous short circuit.

- Cold Resistance: Just as important is the tape’s ability to perform in low temperatures. A low-quality tape can become stiff and unworkable in the cold, making it impossible to apply a proper wrap. Even if you manage to apply it, it may lose its elasticity and become brittle, eventually cracking and failing. A good tape will maintain its flexibility and adhesion down to 0°F (-18°C) or even lower, allowing for reliable installation and performance in cold weather.

Always check the manufacturer’s specifications for the tape’s operating temperature range and ensure it is suitable for the environment where your wiring harness will be installed.

Electrical Rating & Safety Certifications (UL/CSA)

While a wiring harness is primarily a mechanical assembly, its electrical function is paramount. The tape you use provides a critical layer of insulation and safety.

- Electrical Rating: Electrical tape’s ability to resist the flow of electricity is known as its dielectric strength. This is typically measured in volts per mil of thickness. Most standard electrical tapes are rated for up to 600 volts, which is more than sufficient for most automotive and household applications. This rating indicates the maximum voltage the tape can safely insulate. Choosing a tape with a high voltage rating provides an extra margin of safety, even if your application is low voltage.

- Safety Certifications (UL/CSA): For any serious electrical project, a tape’s certifications are non-negotiable. Look for tapes that are UL Listed (Underwriters Laboratories) and/or CSA Certified (Canadian Standards Association). These third-party organizations independently test products to ensure they meet strict safety and performance standards. A UL/CSA Listed electrical tape has been tested for its tensile strength, adhesion, fire retardancy, and ability to resist electrical breakdown under various conditions. When you see these labels, you can be confident that the tape will perform as promised and will not become a safety hazard. Using a certified tape is a professional best practice and is often required by code for commercial or industrial applications.

- Flame Retardancy: This is a crucial feature for any tape used on a wiring harness. In the event of a short circuit, a spark could ignite the tape. A flame-retardant tape is engineered to self-extinguish, preventing the fire from spreading. All UL Listed electrical tapes must be flame-retardant.

Color Options for Wire Identification

While not a functional requirement for protection, the color of your electrical tape is an essential tool for organization and safety.

- Standard Black: Black is the most common color for electrical tape and is used for the outer jacket of a wiring harness. Its neutral appearance provides a clean, professional finish.

- Color-Coding: The real benefit of having a variety of colors is for wire identification. In complex harnesses, different colors are used to identify individual circuits or wire bundles. For example, you might use red tape to mark a power wire, blue for a signal wire, and green for a ground. This makes installation easier and is invaluable for troubleshooting or repairing the harness in the future. Buying a multi-color pack is a smart choice for any DIYer or professional who needs to maintain an organized and traceable system.

Value – Single Roll vs. Multi-Pack

The final consideration is value, which goes beyond just the price per roll.

- Single Roll: A single, high-end roll of a premium tape, like 3M Scotch Super 33+, is the best choice for a small, critical project where performance is paramount. You get a superior product that will last for years, ensuring the integrity of your work.

- Multi-Pack: For larger projects or for a workshop where tape is a frequently used supply, a multi-pack offers the best value. Brands like AmazonCommercial or Lichamp offer good-quality, certified tape in bulk, making it a cost-effective solution for anyone who needs a reliable supply for multiple projects.

When assessing value, consider the tape’s quality, not just its price. A cheap tape that fails after a few months is a poor investment. A slightly more expensive tape that lasts for years is the better value in the long run.

In conclusion, choosing the best electrical tape for a wiring harness is a strategic decision. By carefully considering the material, adhesion, temperature resistance, safety certifications, and practical value, you can select a product that not only protects your wires but also ensures the safety and longevity of your entire electrical system.

What is a Wiring Harness and Why is Proper Taping Crucial?

A wiring harness is an assembly of electrical cables and wires that transmit signals and electrical power. These bundles are custom-designed to fit a specific space, such as the engine bay of a car or the chassis of an appliance. The wires within the harness are often organized by color and insulated, but they require an outer layer of protection to survive their harsh operating environments.

The primary reasons proper taping is non-negotiable for a wiring harness are:

- Abrasion Resistance: Wires can rub against metal parts, causing the insulation to wear down over time. This can lead to a short circuit or an open circuit. A durable tape provides a tough, protective jacket to prevent this from happening.

- Environmental Protection: Engine bays are exposed to heat, oil, fuel, and moisture. An effective tape seals the harness, preventing these contaminants from compromising the wire insulation and causing corrosion or failure.

- Vibration Dampening: The constant vibration in a vehicle can cause wires to rub against each other, generating noise and wearing down the insulation. Tightly wrapping the harness with a conforming tape dampens these vibrations, protecting the wires and reducing noise.

- Organization and Aesthetics: A neatly taped harness is easier to install, troubleshoot, and repair. It gives the project a professional, organized look and ensures that wires are routed correctly and safely, preventing them from tangling or interfering with moving parts.

- Flame Retardancy: In the event of an electrical fault or accident, a high-quality, flame-retardant tape can prevent a small spark from becoming a full-blown fire, offering a critical layer of safety.

Key Features to Look for in a Wiring Harness Tape

Before we review the top products, let’s understand the critical characteristics that set a good wiring harness tape apart from a general-purpose electrical tape.

- Adhesion and Conformability: The tape must stick securely to itself and the wires, even on irregular surfaces and tight corners. High conformability ensures a smooth, wrinkle-free wrap that won’t leave gaps for moisture or debris to enter.

- Temperature and Abrasion Resistance: For automotive applications, the tape must withstand extreme heat and cold. It should also be tough enough to resist friction and wear. Look for tapes rated for a wide temperature range, particularly those certified for high-heat environments.

- Voltage and Flame Retardancy: While most wiring harnesses are low voltage, the tape’s ability to provide a strong dielectric barrier is essential. A tape with a high voltage rating (typically 600V) and a flame-retardant certification adds a crucial layer of safety.

- Durability and Longevity: The tape needs to maintain its properties for years. Low-quality tapes can become brittle, lose their stickiness, or turn into a gooey mess over time. The best tapes are resistant to UV rays, chemicals, and aging.

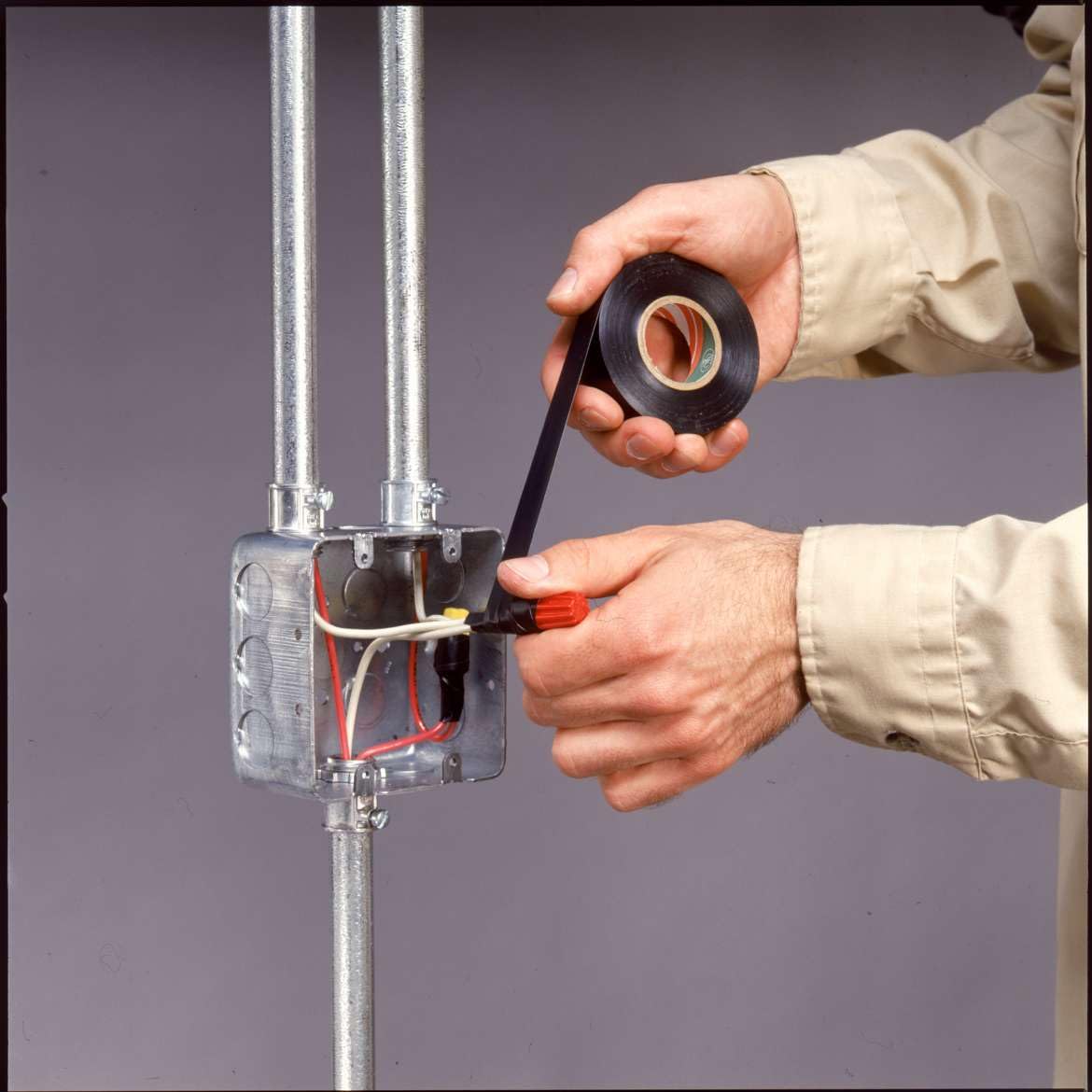

How to Properly Apply Electrical Tape to a Wiring Harness

Even the best tape in the world won’t perform correctly if it’s not applied with care. Proper application is a crucial step to ensure the longevity and safety of your wiring harness.

- Step 1: Clean the Surface. Before applying the tape, make sure the wires and any connectors are free of dirt, oil, and moisture. A clean surface ensures the best possible adhesion.

- Step 2: Start with an Anchor. Begin by wrapping the tape around itself for a full turn to create a strong, stable anchor point. This prevents the tape from flagging (lifting) at the start.

- Step 3: Stretch and Overlap. As you wrap the tape, apply a moderate, consistent stretch. This creates a smooth, tight seal that conforms to the shape of the wires. Overlap each wrap by about 50% of the tape’s width. This half-lapping technique is key to creating a solid, waterproof barrier.

- Step 4: Reduce Tension at the End. For the final turn or two, reduce the tension on the tape. This allows the adhesive to set without the constant pull of a tight stretch, which helps prevent the end from peeling or “flagging” over time.

- Step 5: Press and Seal. Once the tape is wrapped, press down firmly on the final section to ensure the adhesive has a strong bond.

Beyond the Top 5: Other Great Tapes and Alternatives

While PVC electrical tape is the most common choice, other options are gaining popularity for specific wiring harness applications, especially in the automotive industry.

- Cloth/Fleece Tapes: These tapes, such as the widely-used Coroplast brand, are a favorite in European car manufacturing. They provide excellent abrasion resistance, reduce rattling noise, and have a non-sticky feel on the outside, which prevents dirt from clinging to the harness. They are often used alongside vinyl tape for their unique benefits.

- Liquid Electrical Tape: This is a liquid rubber coating that can be brushed on. It is excellent for sealing irregular shapes and hard-to-reach areas where traditional tape cannot be applied smoothly. It cures into a flexible, waterproof, and durable coating.

- Self-Fusing Silicone Tape: This tape contains no adhesive but fuses to itself when stretched and wrapped. It creates a solid, watertight, and temperature-resistant silicone rubber layer. It is an excellent choice for sealing and insulating, but it lacks the abrasion resistance of vinyl tapes.

Frequently Asked Questions about Wiring Harnesses and Tapes

- Is electrical tape a permanent solution? While high-quality electrical tape is designed for long-term use, it should not be considered a permanent fix for broken wire insulation. For a proper repair, use heat-shrink tubing or a wire nut before taping. The tape serves as the final protective layer.

- Why is my electrical tape getting gooey? This is a common problem with low-quality tapes. When exposed to heat, the adhesive on these tapes can break down and melt, leaving a sticky residue. A high-quality, professional-grade tape is formulated to resist this degradation.

- Can I use duct tape instead of electrical tape? No, you should never use duct tape for electrical wiring. Duct tape is not flame-retardant and its adhesive is not designed to withstand heat. It can become a fire hazard and its non-conformable nature makes it a poor insulator.

Conclusion

Choosing the right electrical tape for a wiring harness is a crucial decision that impacts the safety and reliability of your entire system. While it’s tempting to grab the cheapest roll off the shelf, the investment in a high-quality, purpose-built tape pays dividends in the long run.

The 3M Scotch Super 33+ remains the gold standard, offering a superior blend of flexibility, durability, and all-weather performance that is unmatched. However, for those seeking specific qualities, the Duck Professional offers exceptional ruggedness, and the Lichamp tape provides a professional-grade alternative with great resistance to chemicals. For large-scale projects or DIY use, the AmazonCommercial and Cambridge tapes offer excellent value and reliable performance, respectively.

No matter which tape you choose, remember that proper application is key. A well-wrapped harness, secured with the right tape, will be durable, safe, and organized for years to come.

- 10 Best Organic Fertilizers for Winter Crops: The Complete Guide - February 23, 2026

- 10 Best Overwinter Fertilizers for Vegetable Garden in 2026 - February 23, 2026

- 10 Best Fertilizers for Plants and Flowers in 2026 - February 23, 2026